Digital Transformation – Catalyzing a More Nutritious Food System – ICT For Ag 2023

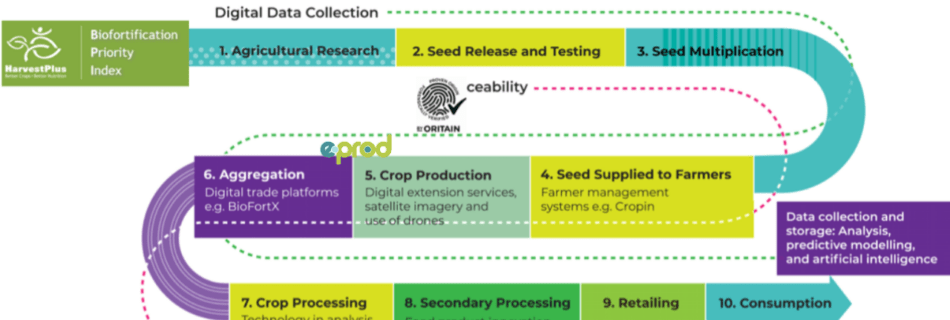

About a year ago, the Harvest Plus team under the IFPRI programme reached out to eProd Solutions with the request to use eProd for the introduction of biofortified seed varieties in Zimbabwe. As much as the seed varieties they promote are appreciated by both farmers and millers, there was an initial resistance on the ground. …

Read more “Digital Transformation – Catalyzing a More Nutritious Food System – ICT For Ag 2023”